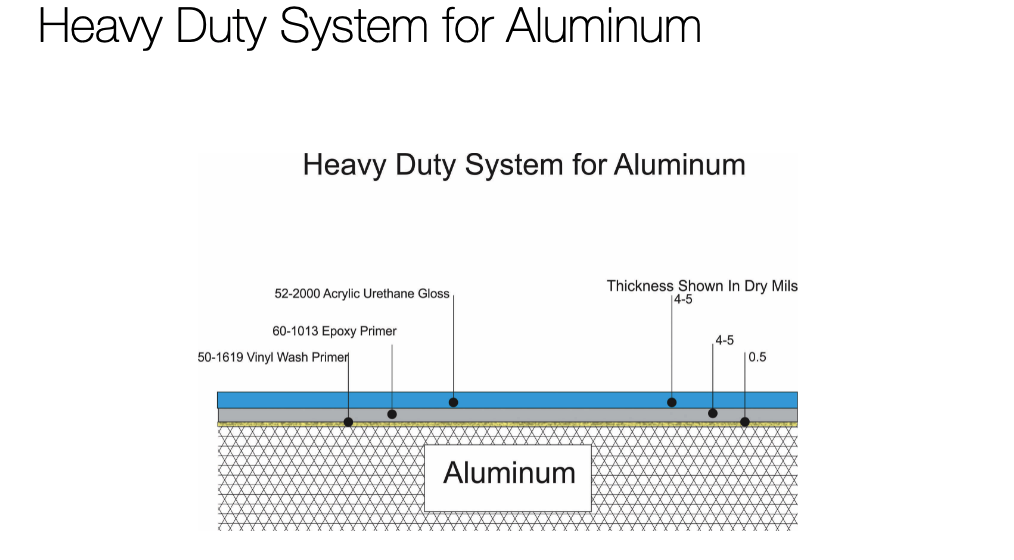

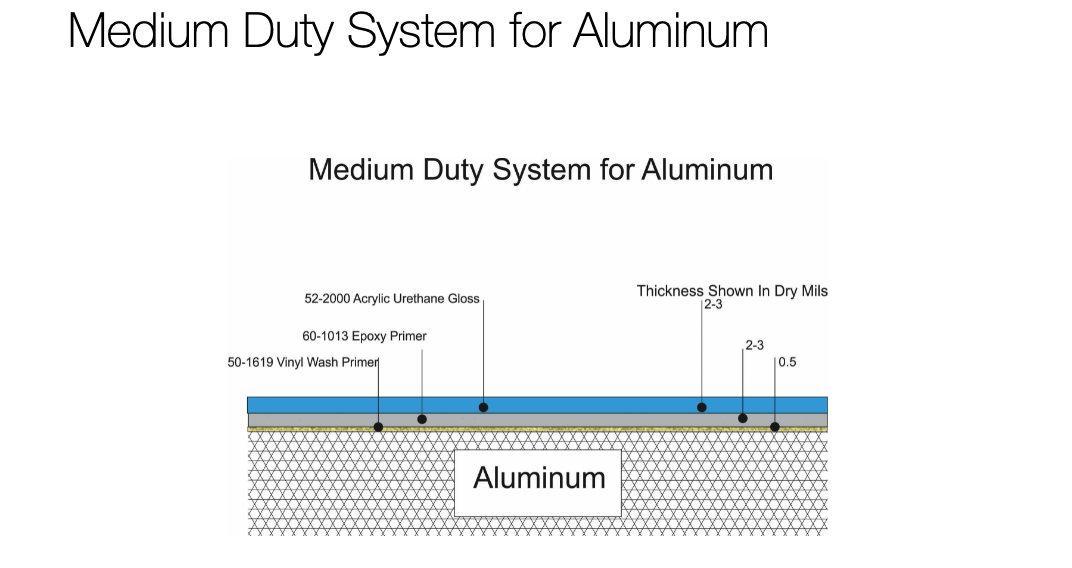

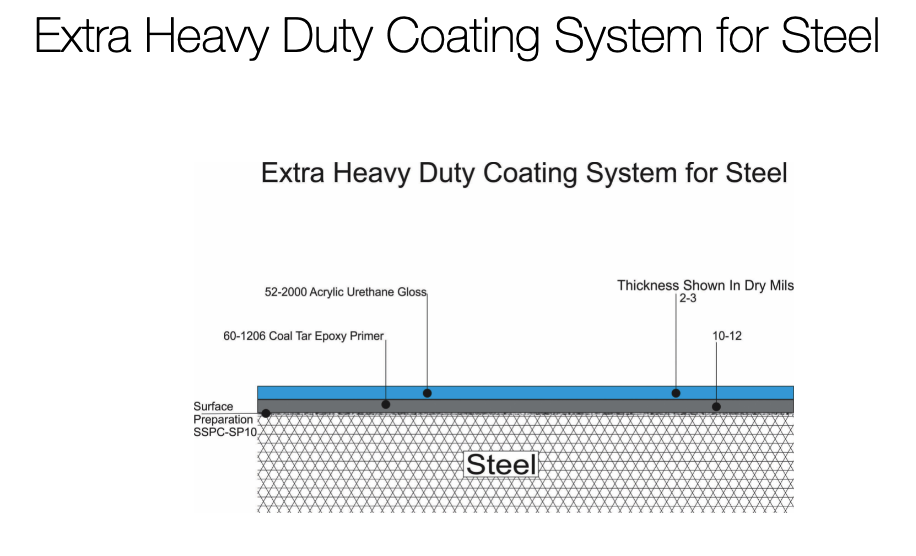

Acrylic Urethane Gloss White – 52-2000

DESCRIPTION

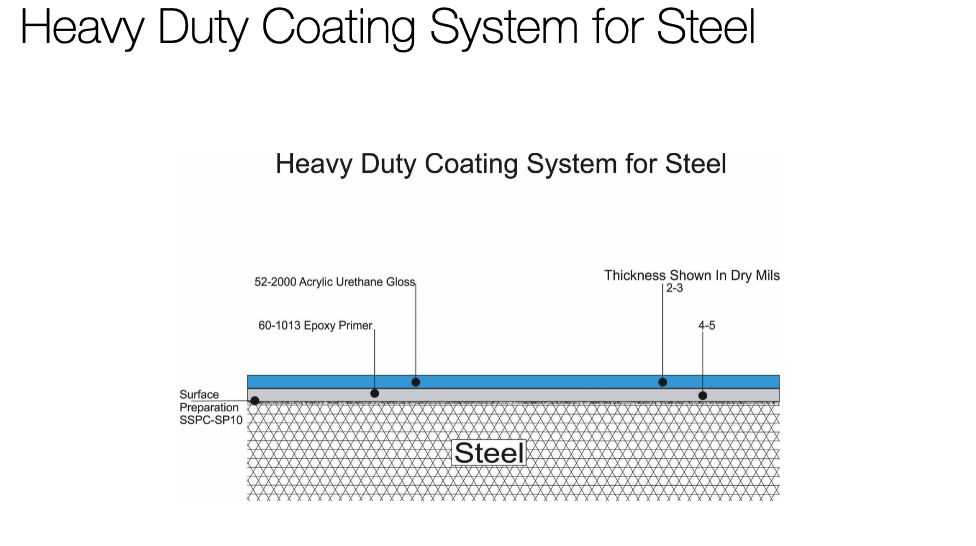

A high build, high performance, two component aliphatic urethane.

INTENDED USES

For use on properly prepared steel, galvanized, aluminum and concrete floors. For use on exterior or interior structural steel, piping, metal buildings, conveyors, pumps, storage tank exteriors, motors, machinery and transportation vehicles.

ACRYLIC-URETHANE-REACTOR-Part-B –

52-2010

DESCRIPTION

A top quality HDI Trimer. Designed for use with 52-2000, 52-2005, 52-2015 and 52-2020. Easy 4:1 by volume mix ratio.

INTENDED USES

This acrylic urethane may be used for exterior or interior industrial maintenance, transportation, marine and product finishing applications where corrosion resistance and long-term protection are important. May be used on various metal substrates, wood, plastics and concrete.

May be blended with Industrial Enamel: 74-0800 series at ½ pint per gallon to increase surface hardness and mar resistance.

Transportation 2 Part Urethane – 52-2500

DESCRIPTION

A high build, high performance, two components aliphatic urethane.

INTENDED USES

For use on truck fleets, railcars, vans, boats, properly prepared steel, storage tank exteriors, motors, machinery and other transportation vehicles.

DESCRIPTION

Recommended for exterior and interior ferrous metal surfaces. Use on machinery, piping, heavy equipment and industrial metal.

INTENDED USES

Ferrous Metal Surfaces, Aluminum Surfaces, Use to topcoat with a primer.

Epoxy Floor Enamel Part A – 60-8000

Epoxy Floor Enamel Part B – 60-8001

DESCRIPTION

A high build polyamide epoxy coating with a two part tough, durable finish. Used in conjunction with epoxy Pt.A 60-8001. Epoxy Enamel exhibits excellent resistance to oils, grease, hydraulic oils, gasoline, aircraft deicer and many other items. Also resists cleaning agents such as TSP and other detergents. Recommended for exterior and interior concrete and metal surfaces. Formulated for heavy duty floor coating applications such as industrial manufacturing areas, heavy traffic warehouses, aircraft hangers and automotive repair and showroom floors.

INTENDED USES

Ferrous Metal Surfaces, Aluminum Surfaces,Concrete and Wood.

DTM Urethane Gloss White – 52-2200

DESCRIPTION

A two component urethane used on direct to metal application.

INTENDED USES

For use on properly prepared steel, galvanized, and aluminum. For use on exterior or interior structural steel, piping, metal buildings, conveyors, pumps, storage tank exteriors, motors, machinery.

DESCRIPTION

A top quality two component acrylic urethane. Easy to apply this acrylic urethane provides excellent environmental resistance to corrosion, abrasion, chemicals and impact. Outstanding gloss and colour retention is shown on exterior exposure. Easy 4:1 by volume mix ratio. 52-2015 Part A black. 52-2010 Part B Acrylic Urethane Reactor.

INTENDED USES

This acrylic urethane may be used for exterior or interior industrial maintenance, transportation, marine and product finishing applications where corrosion resistance and long-term protection are important. May be used on various metal substrates, wood, plastic and concrete.

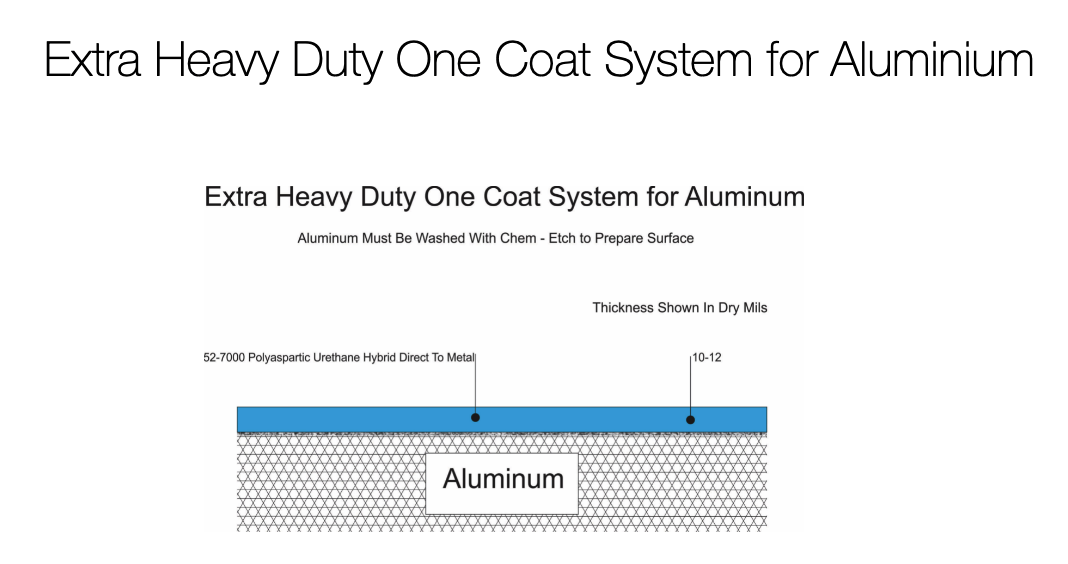

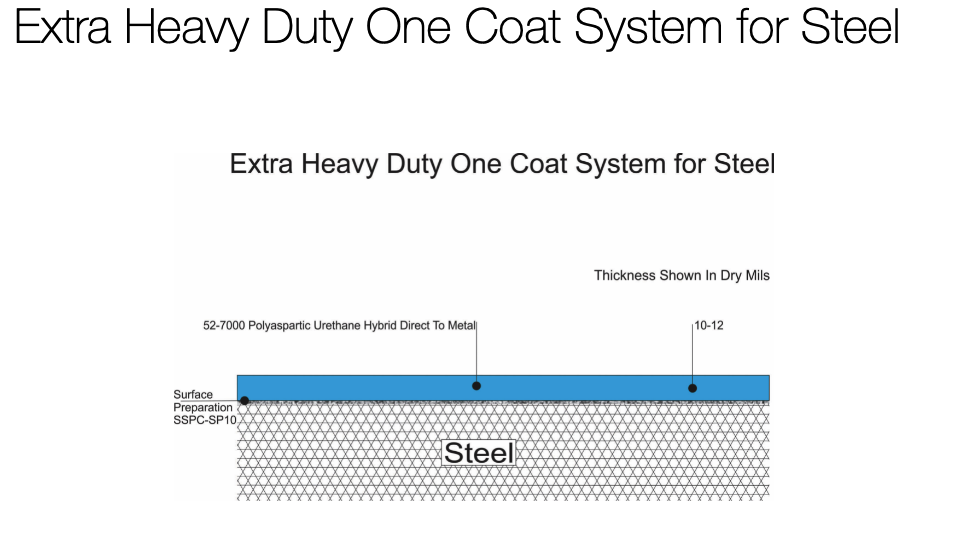

Polyaspartic Urethane Gloss – 52-7000

DESCRIPTION

A high build, high performance, two components aliphatic urethane.

INTENDED USES

For use on properly prepared steel, galvanized, aluminum and concrete floors. For use on exterior or interior structural steel, piping, metal buildings, conveyors, pumps, storage tank exteriors, motors, machinery and transportation vehicles. Can be used on heavy service areas for food processing, dairies, restaurants, hospitals, showrooms and arenas.

Low Temp Baking Alkyd Enamel – 58-8015

DESCRIPTION

A high quality low temperature alkyd based gloss baking enamel. Excellent hiding, extremely durable with excellent weathering and water resistance. Recommended for exterior and interior ferrous metal surfaces. Use on machinery, piping, heavy equipment and industrial metal.

INTENDED USES

For industrial use on all metal surfaces where a durable, decorative finish is necessary and speed of dry is essential,

May be used as a process coating on manufacturing lines where speed of dry is essential. Used on machinery, implements, tools, racking and shelving.

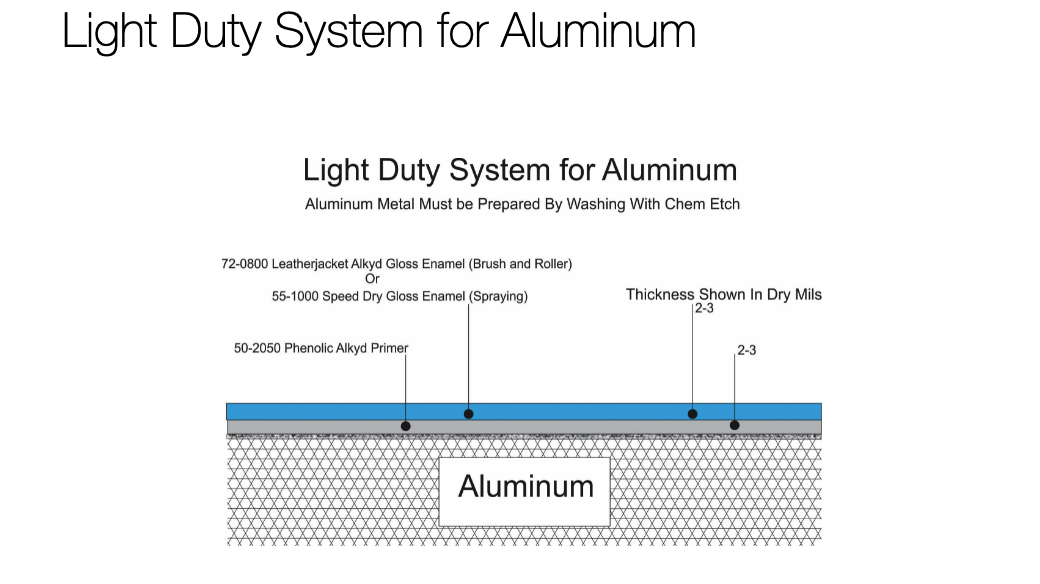

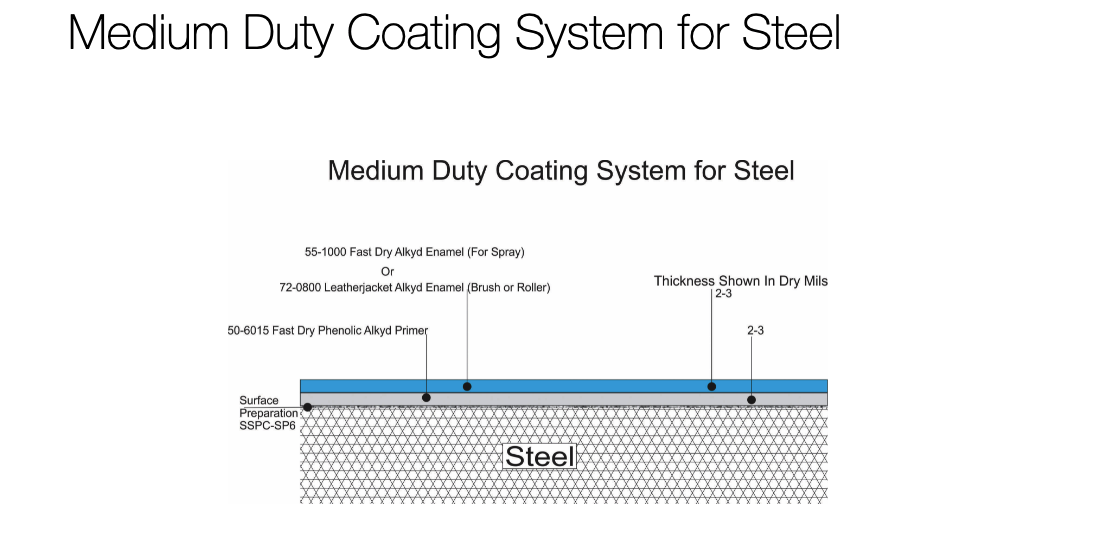

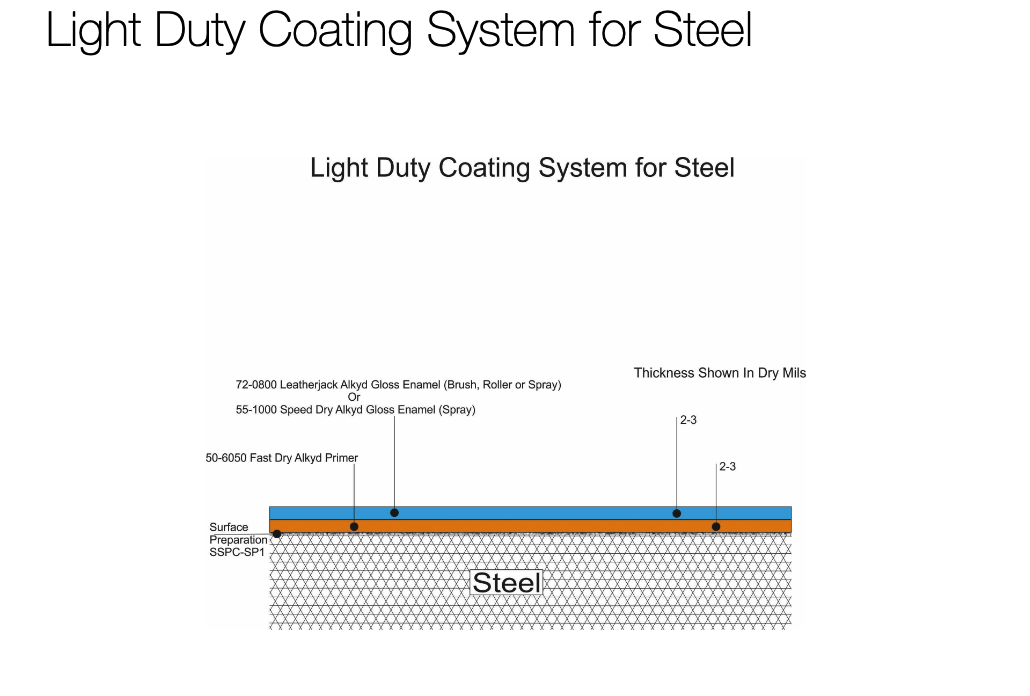

Leatherjacket High Gloss Alkyd Enamel – 72-0800

DESCRIPTION

A high quality, high gloss enamel with a higher than average solids content. Can be applied by brush, roller or spray. Excellent hiding, flexible and durable with excellent weathering and water resistance. Recommended for exterior and interior ferrous metal surfaces. Use on machinery, piping, heavy equipment and industrial metal.

INTENDED USES

Ferrous Metal Surfaces, Aluminum Surfaces, Use to topcoat with a primer. Can be applied over wood, steel, aluminum and fiberglass

steel SYSTEMS

Aluminum SYSTEMS